Assistance

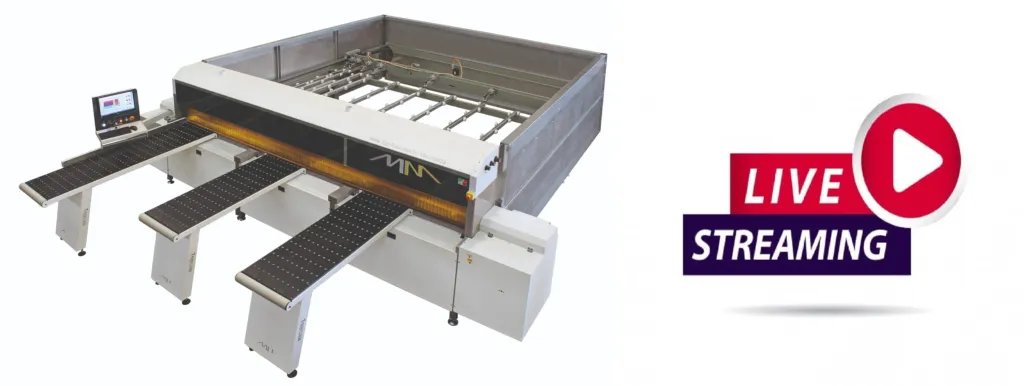

Request by e-mail at the address service@macmazza.it a virtual appointment. You will get a live streaming appointment. You will have to open this page at the appointed time. You will see the TS90 machine live.

Here is what you can request:

- Execution of a cutting program that you send us by mail

- Demo demonstration of the TS90 machine

- Overview of the panel saw program

- Presentation of the optimizer

Faster and more targeted assistance thanks to triangular assistance

The Macmazza service has a “TESTER” horizontal panel saw. This machine is put online and used to speed up and simplify communication with the customer during the service process. It is used in other circumstances such as recreating the problem encountered by the customer. It is used for training purposes and also for demonstration cases.

“Let’s get closer to the customer through online assistance.”

A. Storoni