Description

Top level Vertical Panel Saw born from Macmazza’s experience of over 50 years on horizontal cutting systems.

The solid steel frame with 5 support feet guarantees stability and high structural rigidity. The 5 support feet allow greater stability in the case of uneven floors and with little grip for the fixing bolts.

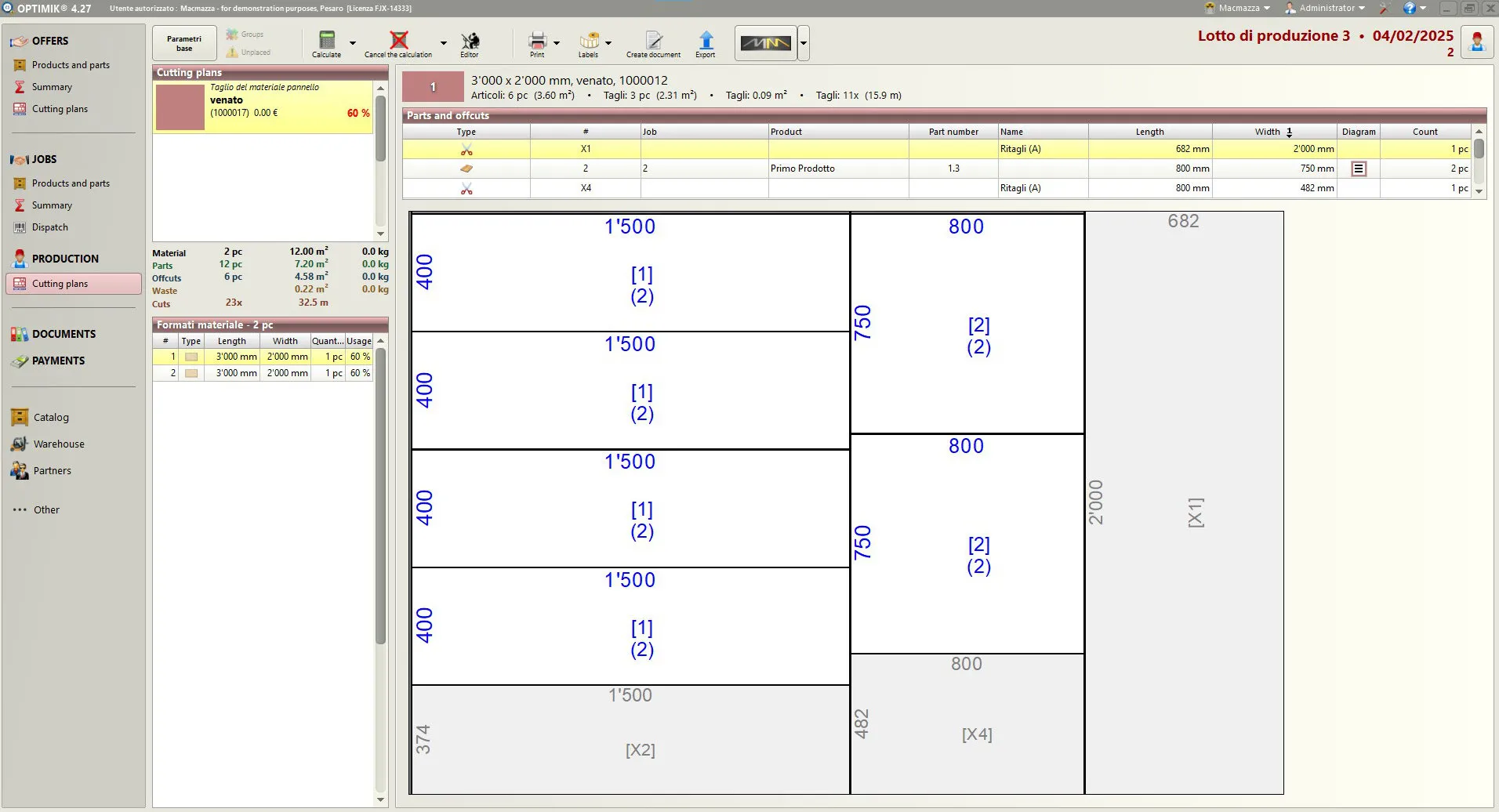

The presence of the Macmazza know how software allows the TS-V to integrate with the entire range of panel saws, guaranteeing a complete and high-performance cutting optimizer in the design and management of waste on an entry level product.

All products comply with the current CE regulations in force for dust extraction, noise and safety.

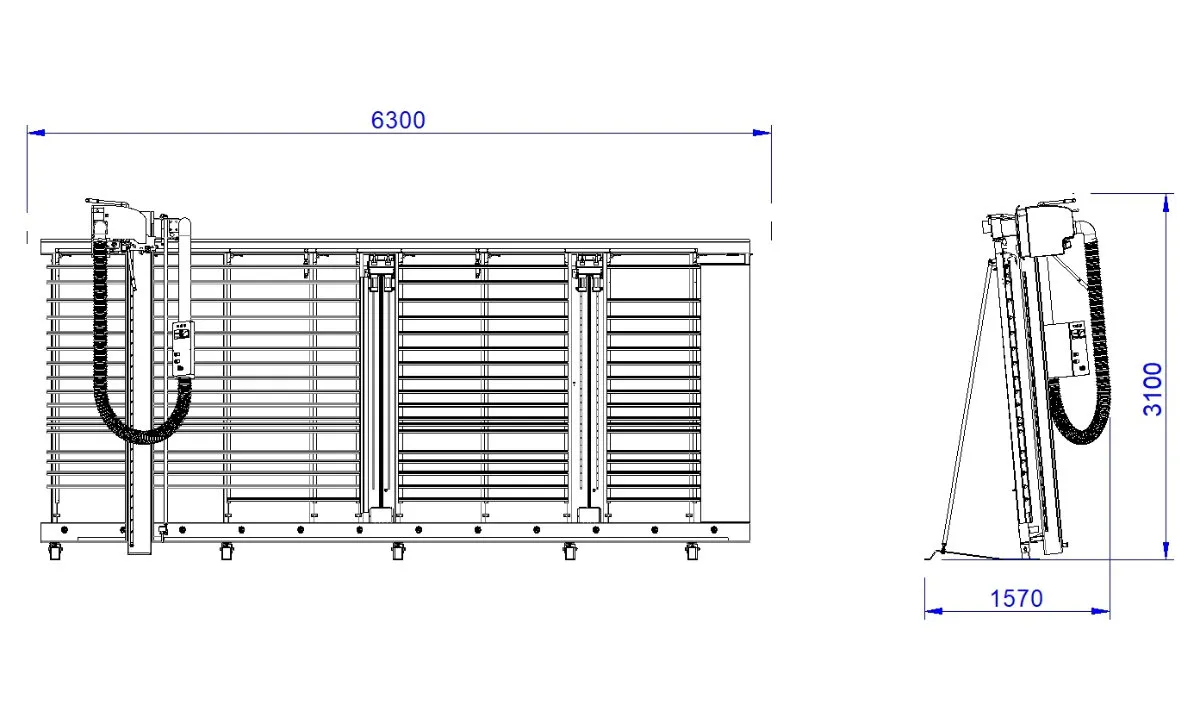

Dimensions

STRENGTHS POINTS

GRIPPERS (on ball screws) allows the use of a single operator both during the processing phase and the set-up phase, saving personnel and manpower hours.

SCORING BLADE The standard Scoring Blade (that can be excluded) allows for perfect cuts on any type of panel.

ELECTRONIC DISPLAYS with decimal measurement display, to ensure the correct positioning of: blade carriage, clamps and transversal stop, to ensure the best dimensional tolerance

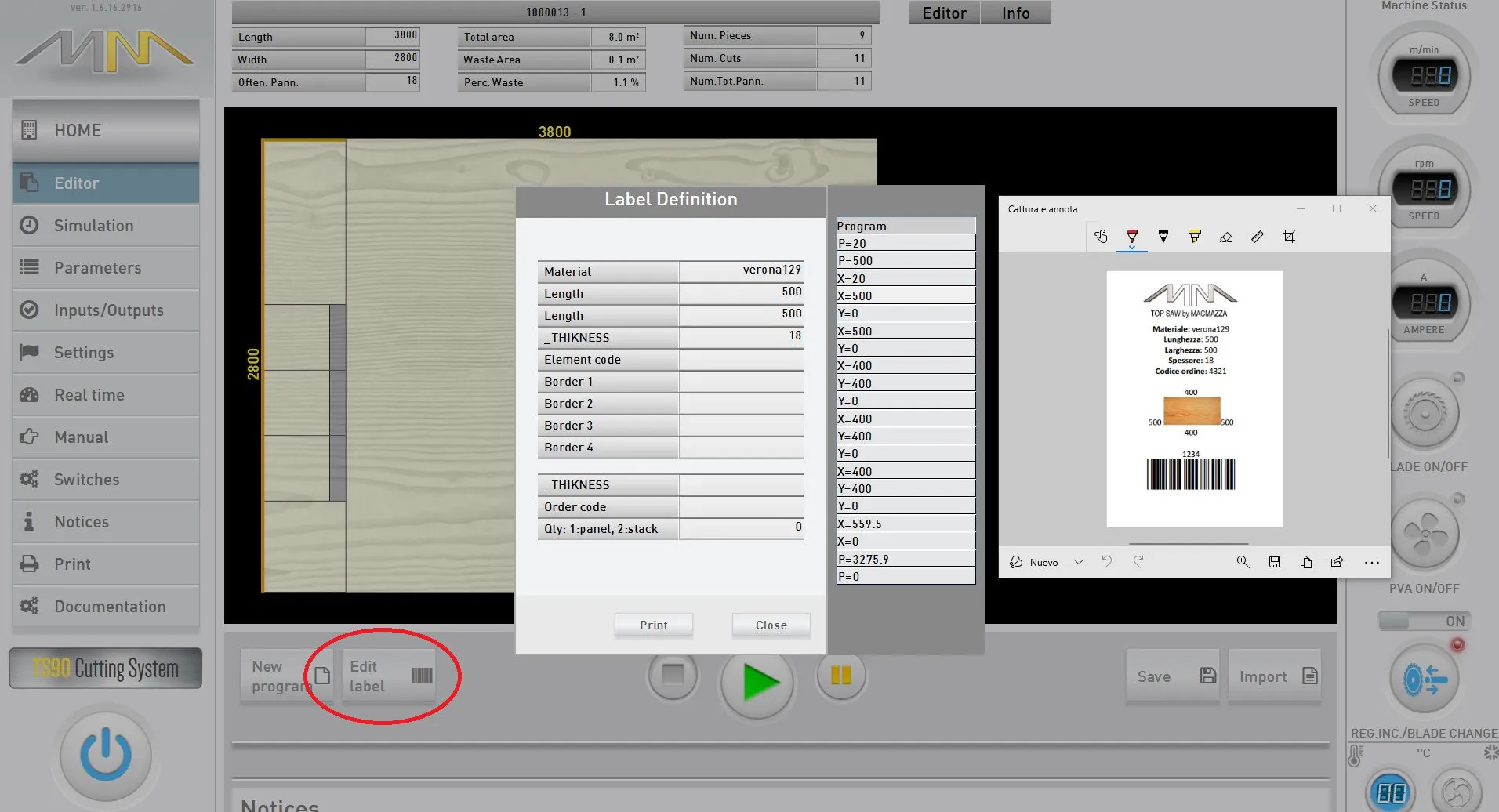

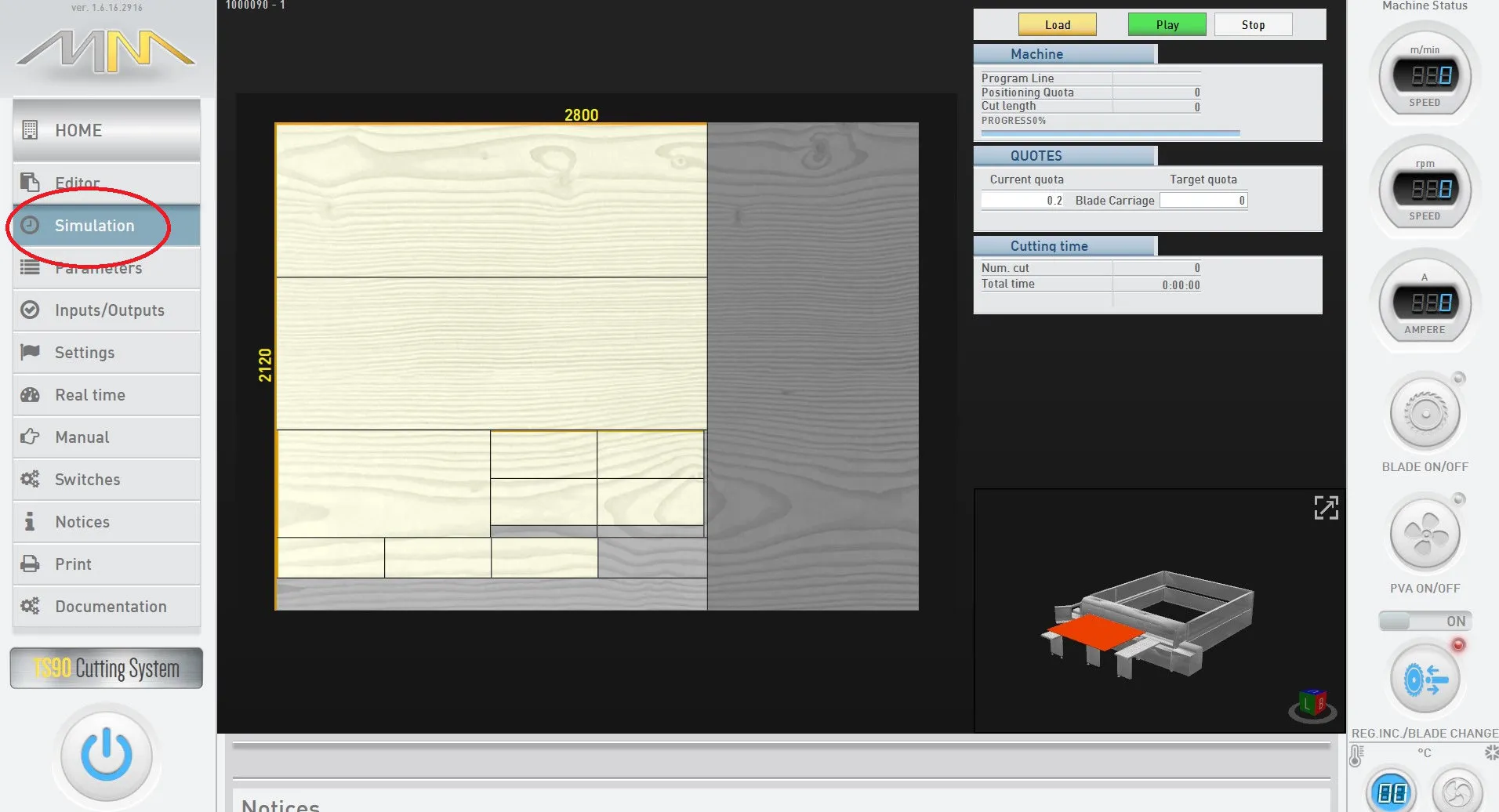

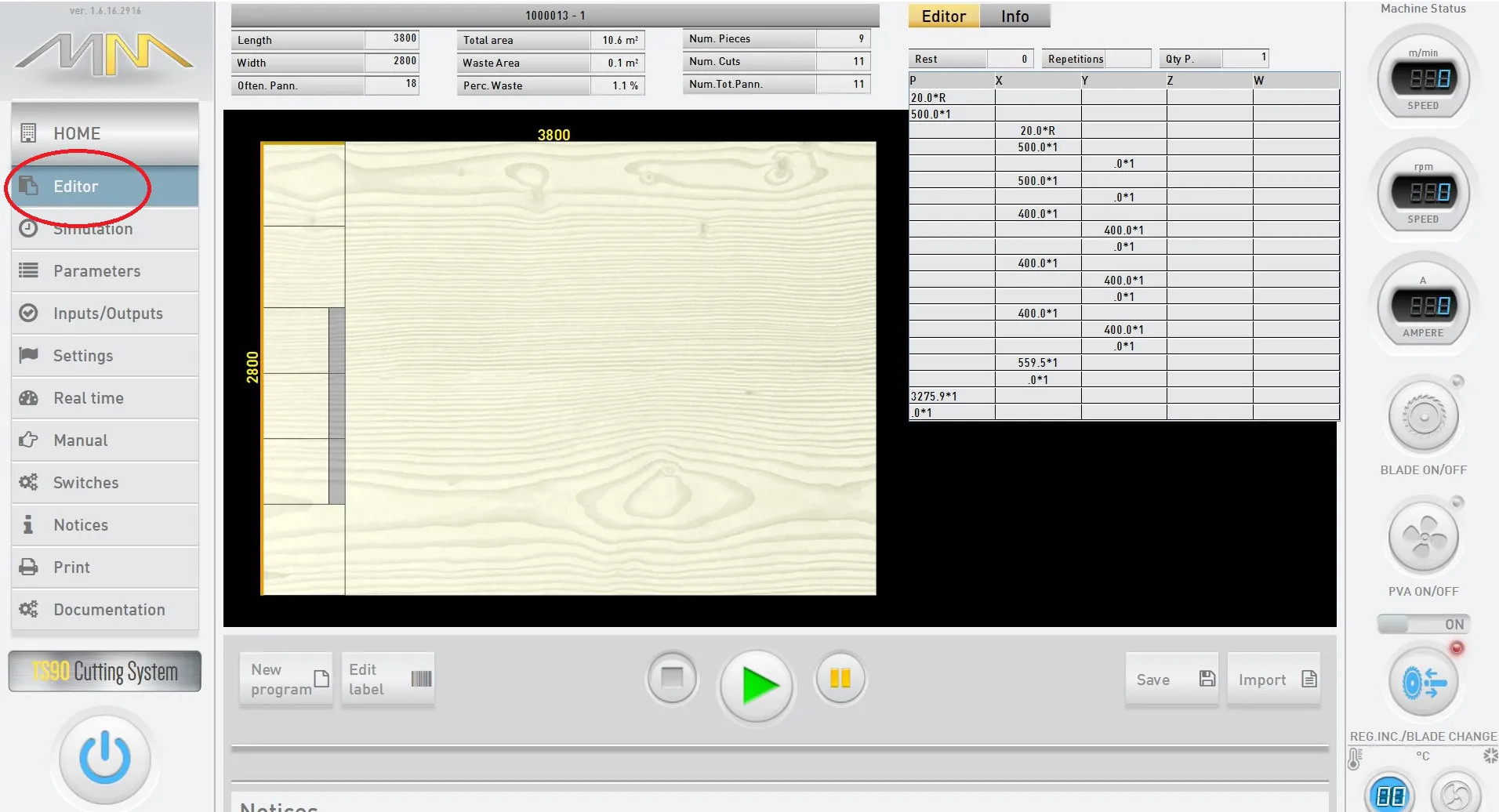

SOFTWARE (Optional) for cutting display program and waste-saving full optionals optimization, with PC and label printing on board the machine application

DUST SUCTION There are 2 dust suction outlets (one on the blade unit and the other on the right side of the base where sawdust tends to accumulate). as per the new CE regulations

Video

Electro-pneumatic system to assist the operator in cutting panels of length 2200 mm with constant feed for maximum cutting capacity.

Complete stop safety device to block movement in the event of incorrect position of the cutting head.

Dedicated accessories

Carriage on wheels

Dedicated software

Products, optionals, accessories

Electro-pneumatic system to assist the operator in cutting panels of length 2200 mm with constant feed for maximum cutting capacity.

Complete stop safety device to block movement in the event of incorrect position of the cutting head.

PC + label printer + cutting program with cutting pattern display on the machine.

Unlimited optimization program in the office or on the machine.

Complete CAD design of the parts, without any size limit.

Possibility of also programming pre-cuts to obtain minimum waste.

Additional office program license including optimization interface.

Storage of panels and parts to be recycled, indication of edges from the edgebanding warehouse.

Technical sheet

| Cutting length | 5100 mm |

|---|---|

| Vertical cutting height | 2200 mm |

| Max height of horizontal cutting | 2200 mm |

| Cut thickness (with pliers) | 60 mm (50 mm) |

| Motor power | 4 hp – 3 kW |

| Main blade diameter | 250 mm |

| Turns main blade | 5800 rpm |

| Scoring diameter | 80 mm |

| Turns scoring blade | 7800 rpm |

| Weight | 1000 Kg |

| Dust extraction hood diameter | 2 x 60 mm |

Quality

High quality mechanical components, long life and reliability.

Efficiency

Compact and high-performance. Quick setup and simplified production processes. Greater automation and flexibility in the costing of the final product.

Easy to use

Intuitive, fast and efficient software. Work lists for easy production start-up.

Environment

Suction system for a clean and comfortable environment.