Top Saw P

Heavy duty automatic panel saw, characterized by solidity, reliability over time and high performance.

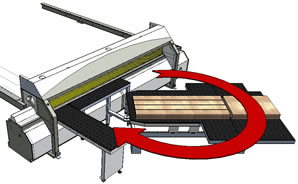

This model includes the rear loading platform

4300 mm cutting line and 110 mm cutting height

The structure of this machine allows any type of customization, according to the customer’s requests.

Workable materials:

- wood

- aluminium

- plastics

- composites

Description

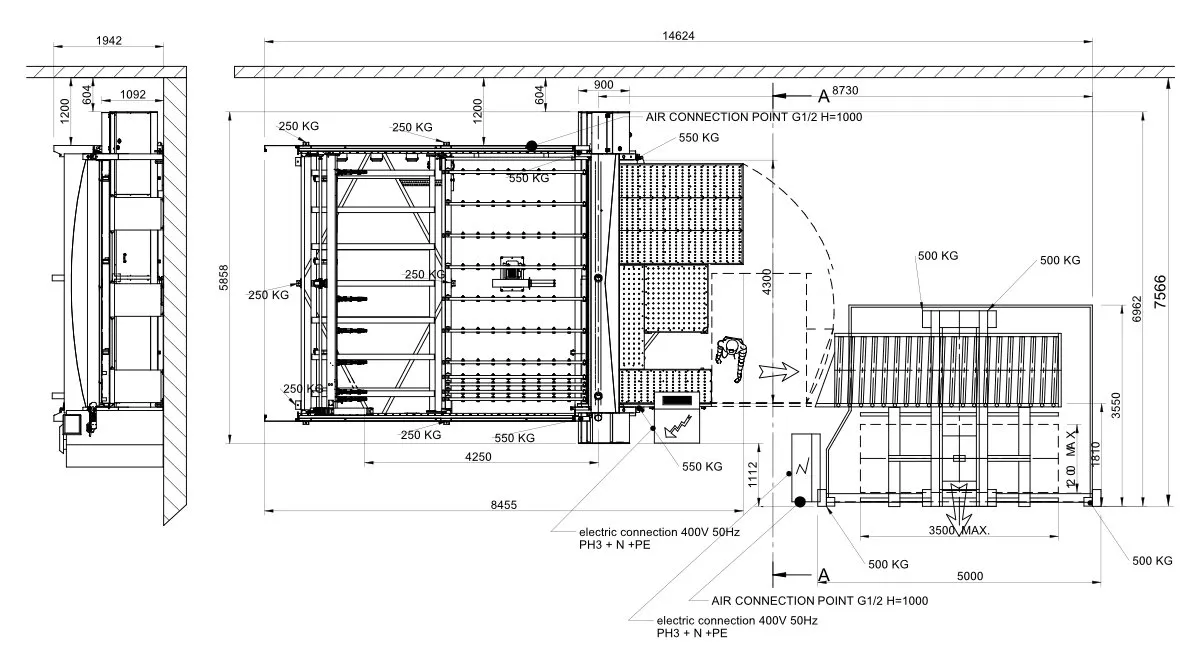

The TOP SAW P panel saw, with a cutting line of 4300 mm, takes up a space of 5860 mm, which is the same space required by competitors who cut 3200 mm.

Macmazza’s Top Saw stands out for its combination of efficiency, precision, solidity and technological innovation, making it an ideal choice for companies looking for advanced solutions for cutting panels.

Designed to offer high performance in cutting wood, aluminium, plastic and fiber cement panels, it is the ideal system for reliability, solidity and durability over time. The automatic rear loading allows for a defined and efficient workflow, with the possibility of loading a standard 600 mm high pack and a maximum capacity of 65 q.

The platform structure is monolithic and reinforced by crosspieces to avoid damage over time due to the loading of the panel packages.

All products comply with the current CE regulations in force for dust extraction, noise and safety.

Dimensions

STRENGTHS POINTS

PRECISION AND QUALITY: Top Saw P guarantees precise cuts, minimizing material waste and improving the quality of the final product.

VERSATILITY: The patented rotating air flotation table allows you to easily handle thicker wood, plastic, aluminium and fiber cement panels, simplifying the cutting process even for heavier materials (hardness up to 150 mm of solid aluminium and soft glass wool).

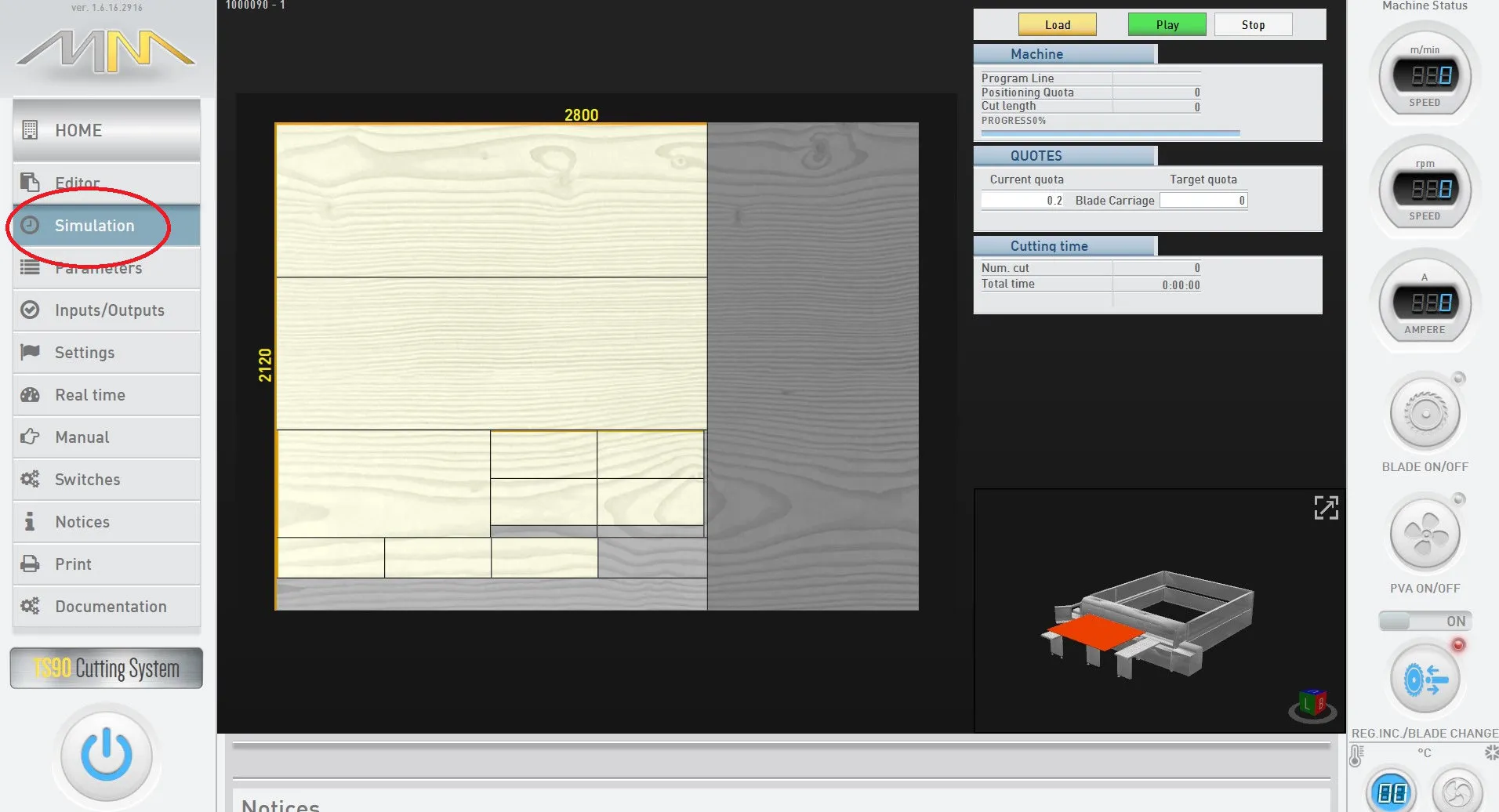

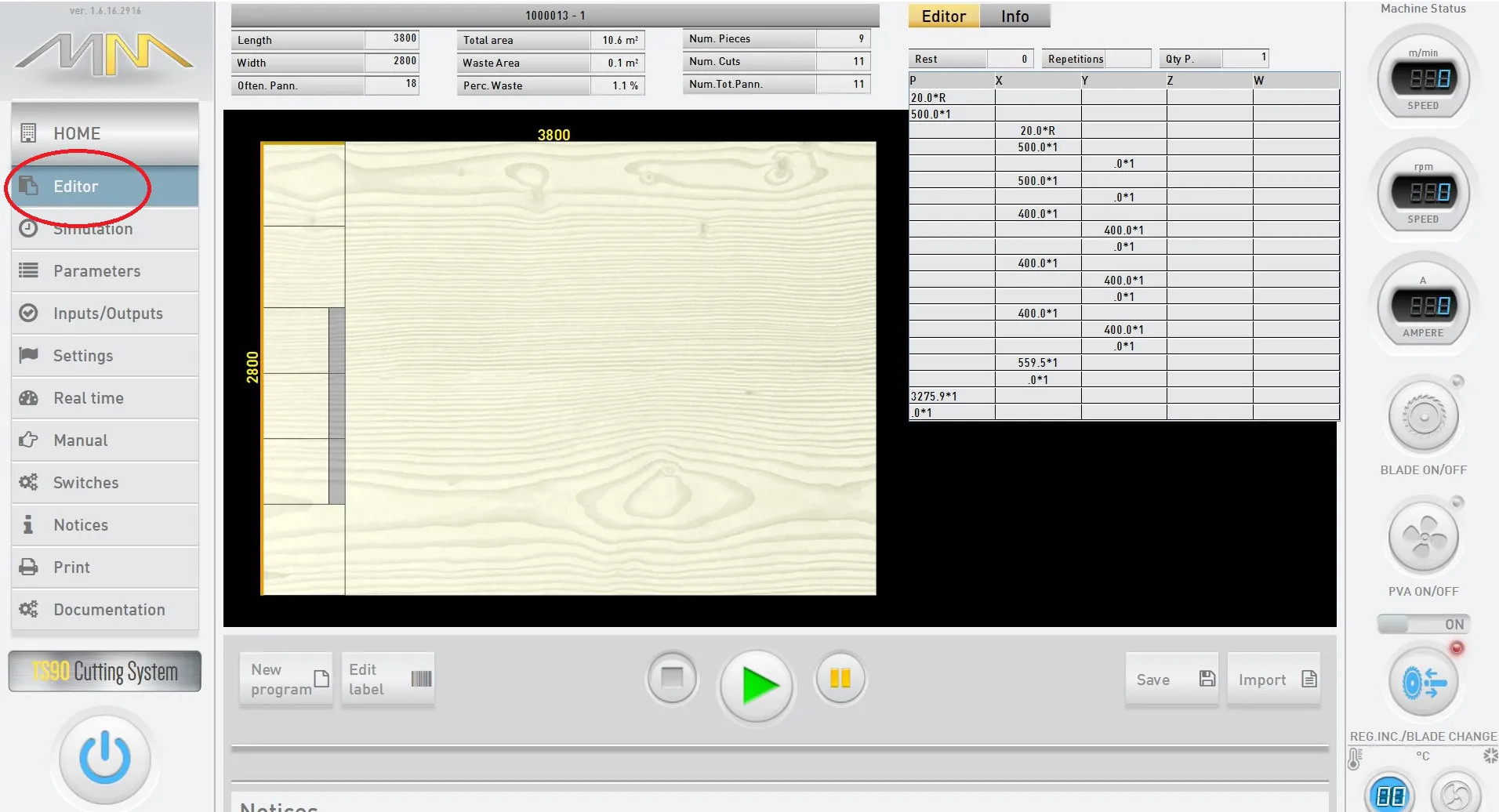

PRODUCTIVITY: With the ability to work with cutting speeds of up to 130 m/min and a pusher speed of up to 90 m/min, the machine is extremely fast, improving overall productivity. In addition, the ability to manage cuts in 5 levels helps reduce waste to a minimum.

SOLIDITY: With a solid construction and a main motor that can vary from 15 to 30 HP, the machine is designed to ensure a long operational life and withstand intensive production cycles (up to 3 work shifts per day)

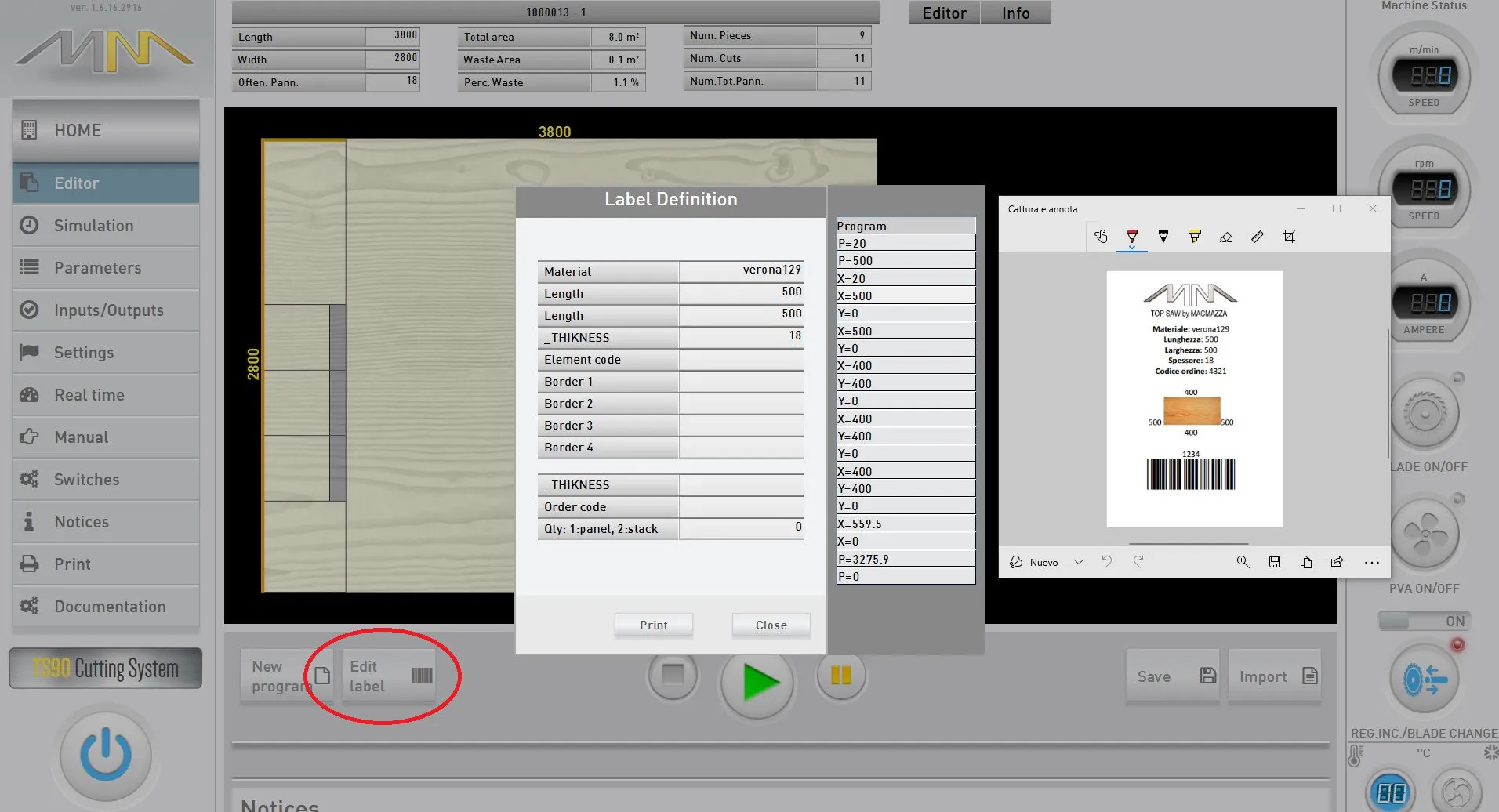

EASY MANAGEMENT: The intuitive management system allows you to quickly manage materials and operations, reducing the risk of errors and improving ease of use for operators.

DIMENSIONS: With a cutting length of up to 4300 mm and a useful cutting height of up to 110 (6 panels of 18 mm), the machine is versatile and suitable for a wide range of industrial needs, from cutting thin materials to thicker ones.

Video

Dedicated accessories

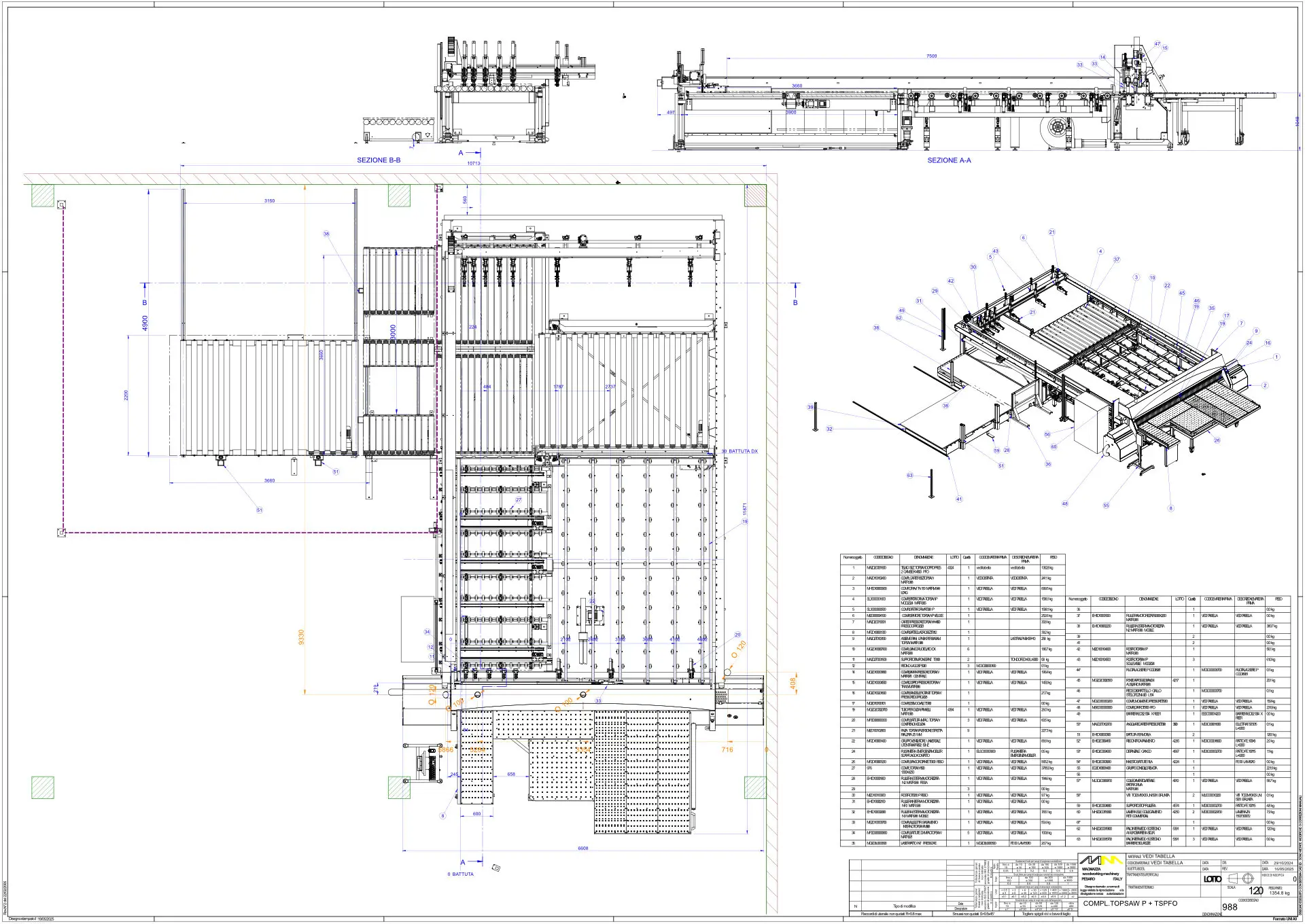

ROTATING AIR FLOTATION TABLE The patent that integrates perfectly with the “Piero” system, solves the problem of complex frontal movement in single-blade panel saws, especially when dealing with complex cutting patterns. This device is particularly useful for advanced optimizations at 5 cutting levels, reducing waste and maximizing efficiency with less manpower.

The main improvements introduced by the combination with the Rotating Air Flotation Table on the Top Saw panel saw include:

- The system allows you to easily rotate not only pre-cuts or head cuts, but also packs of longitudinal strips for cross cuts, without operator effort and without the need for rails or guides.

- It allows you to make complex cuts to optimize panel waste with a single operator, improving productivity and reducing labour costs.

- It is more economical than a rear-loading platform.

- Compared to automatic rotating systems, our system is faster and safer, avoiding damage to panels, even thin or delicate ones.

- The divisible tables allow loading and unloading directly from the front of the machine, with ease of operation with a forklift or forklift.

- The system allows a continuous flow of work, without stopping the cutting cycle, and facilitates the unloading of large packages or strips.

- When the table is rotated, it is possible to load and unload from both sides of the machine, optimizing space.

- For small panels, the operator can work directly in the cutting area, while for large panels, the operator moves laterally.

- The table can be easily integrated with automatic systems for loading and unloading panels.

- The mechanical device is simple, robust, requires no maintenance or adjustments, and includes safety photocells to prevent incorrect use.

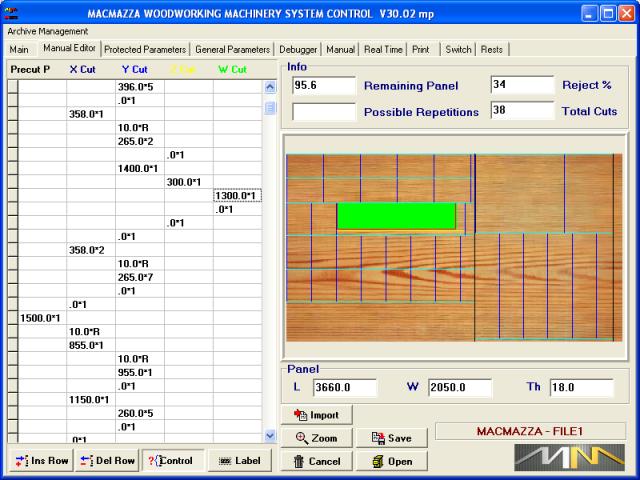

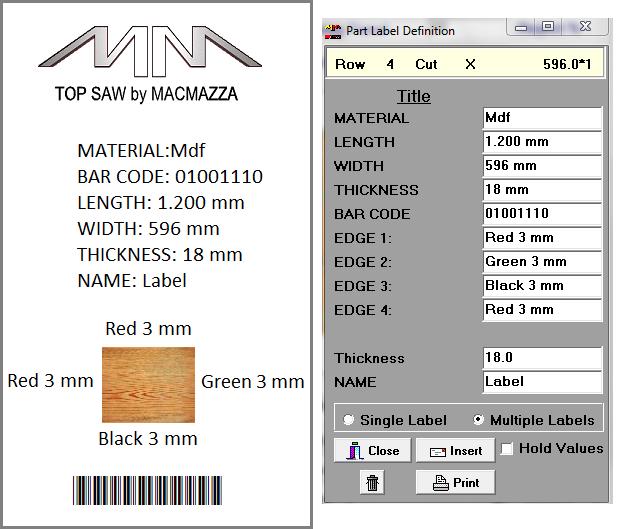

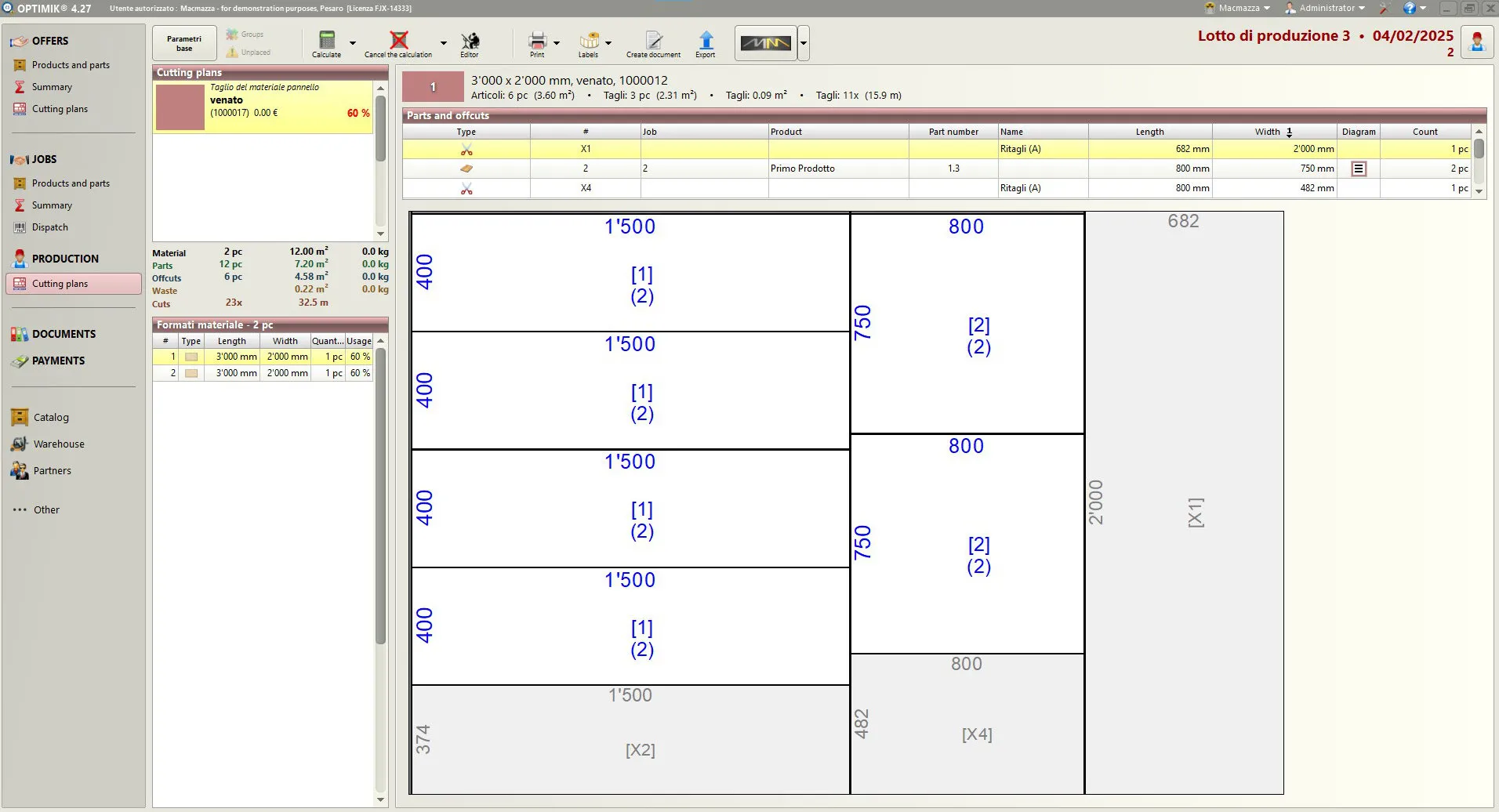

Dedicated software

PC + label printer + cutting program with cutting pattern display on the machine.

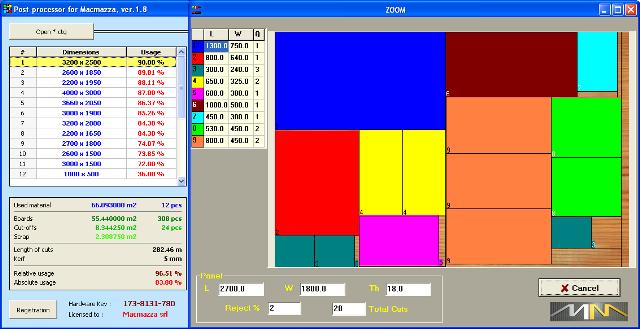

Unlimited optimization program in the office or on the machine.

Complete CAD design of the parts, without any size limit.

Possibility of also programming pre-cuts to obtain minimum waste.

Additional office program license including optimization interface.

Storage of panels and parts to be recycled, indication of edges from the edgebanding warehouse.

Products, optionals, accessories

Flexible warehouse “PIERO”

Rotating air flotation table

INDUSTRY 5.0 Application of double inverter for blade shaft rpm variation, with the following advantages:

- optimize the cutting speed depending on the required quality and the type of material.

- optimization of the motor power to avoid overheating, reduce weight and carry out significant energy savings (at least 30% of current)

- greater feed speed and lower consumption of blades.

- Air blow for blade cooling, gluing powders and greater cleanliness.

Top Saw PP

TS PP ultra-flexible and space-saving single-blade panel sizing machine with dual loading platform to alternately select a prebordered/postformed bar load OR classic panel load from other rear automatic load, then with two independent rear loading platforms and front air curtain turntable for easy handling and connectable to in-line automatic unloading.

Layout

Video

Technical sheet

| Cutting length |

4300 mm – custom |

|---|---|

| Effective Cutting Height |

110 – 80 mm post forming |

| Motor power |

18 – 30 hp |

| Main blade diameter |

350 min – 400 max (mm) |

| Weight |

8000 kg |

| Dust extraction hood diameter |

2×120 mm 2×100 mm |

| Velocità avanz carro lame |

3-70 m/min |

| Saw carriage return speed |

60-140 m/min |

| Pusher speed |

2÷50 m/min |

| Pusher return speed |

40-90 m/min |

| Suctions |

4000-5500 m³/h 2000-5000 pa |

Quality

High quality mechanical components, long life and reliability.

Efficiency

Compact and high-performance. Quick setup and simplified production processes. Greater automation and flexibility in the costing of the final product.

Easy to use

Intuitive, fast and efficient software. Work lists for easy production start-up.

Environment

Suction system for a clean and comfortable environment.