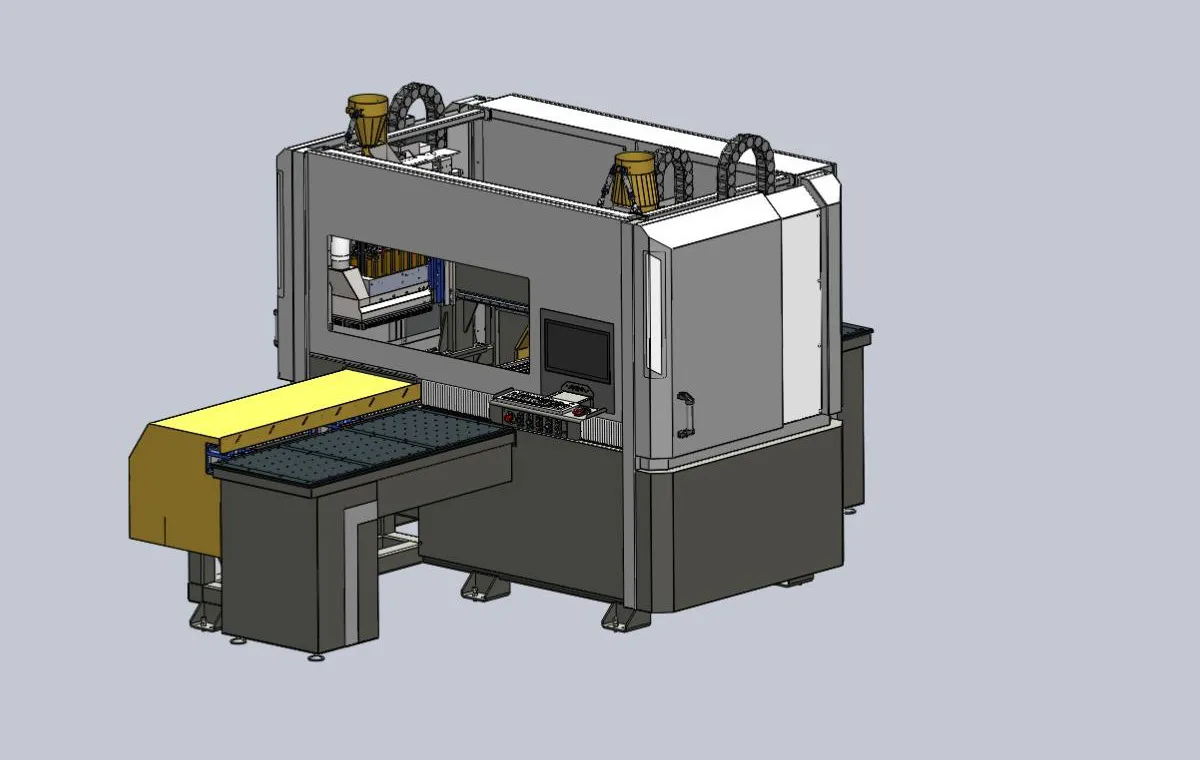

Description

Drilling and milling cnc machine with pass-through panel complete with DOUBLE upper and lower drilling head , electrospindle, DOUBLE gripper for dragging the panel and front and rear pneumatic presser. Top and Bottom drilling unit.

DRILLINGS ON ALL 6 FACES OF THE PANEL

PANEL SQUARING ON 4 SIDES AND POSSIBILITY OF CARRYING OUT THROUGH-THROUGH EMPTYINGS.

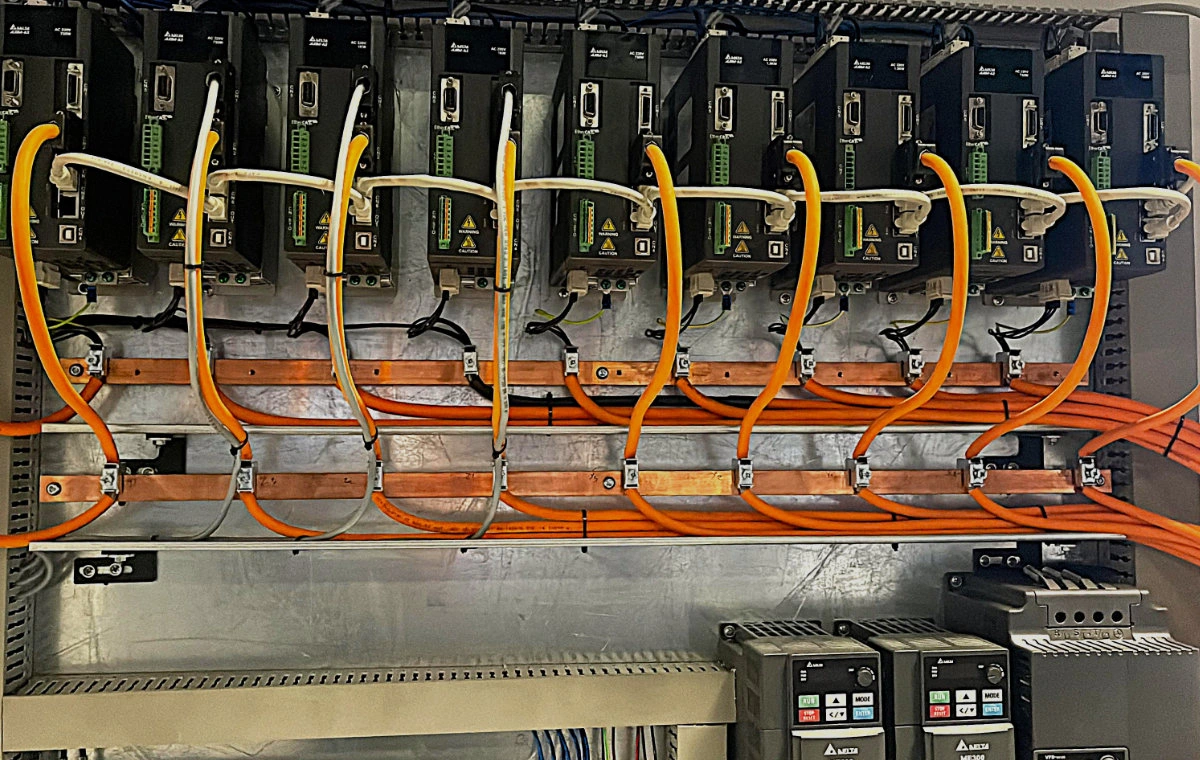

Thanks to digital drives and fiber optic connections, absolute precision and high working speed are guaranteed. The software manages the parking of the head near the access door, to easily change tips, blades and cutters

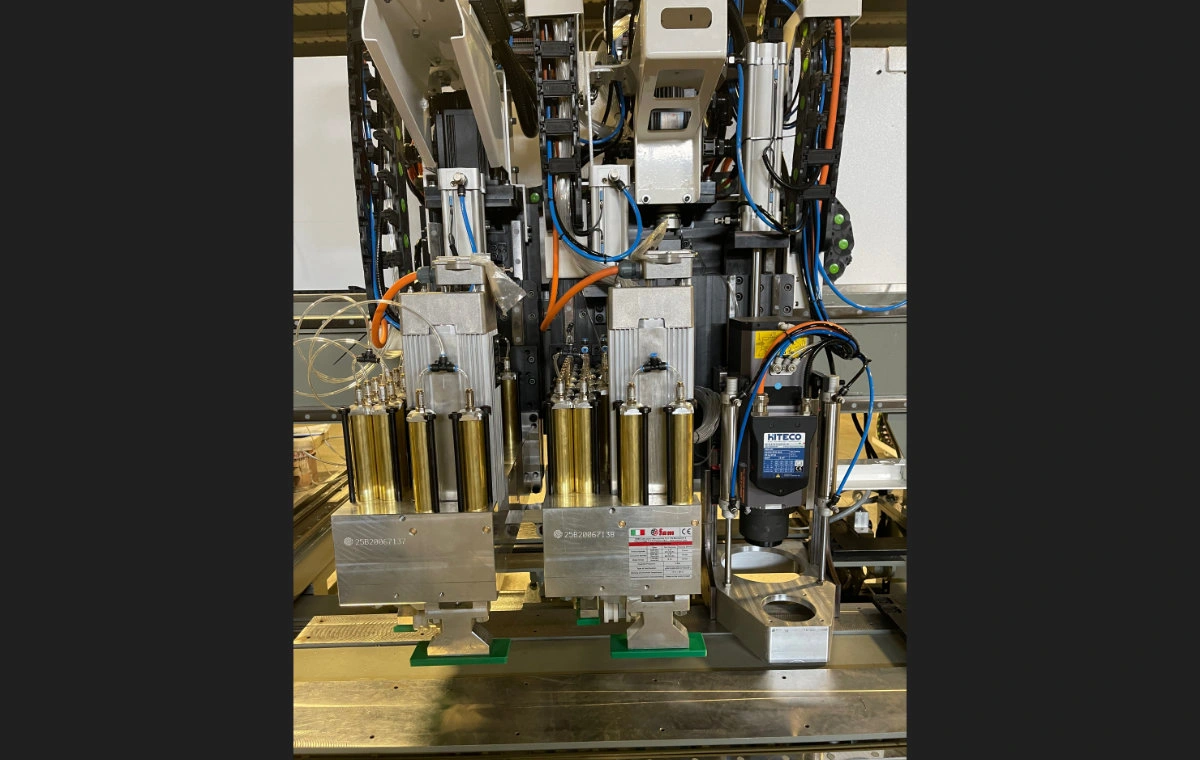

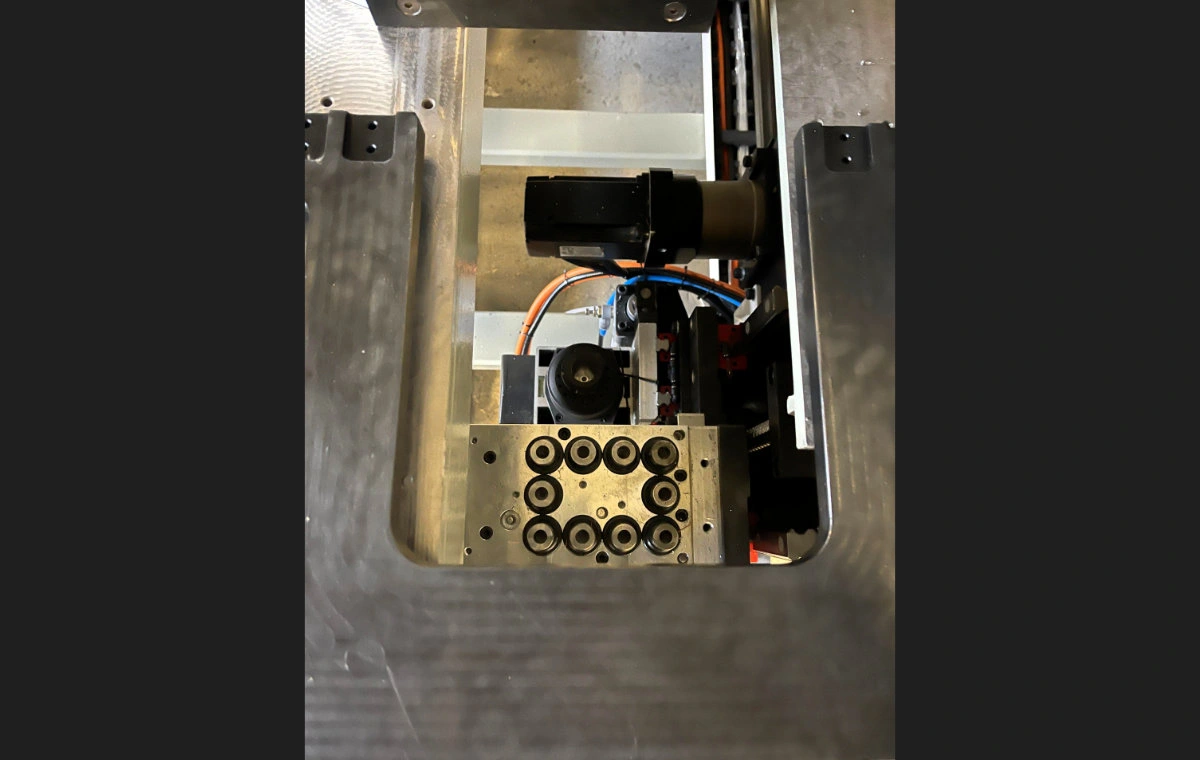

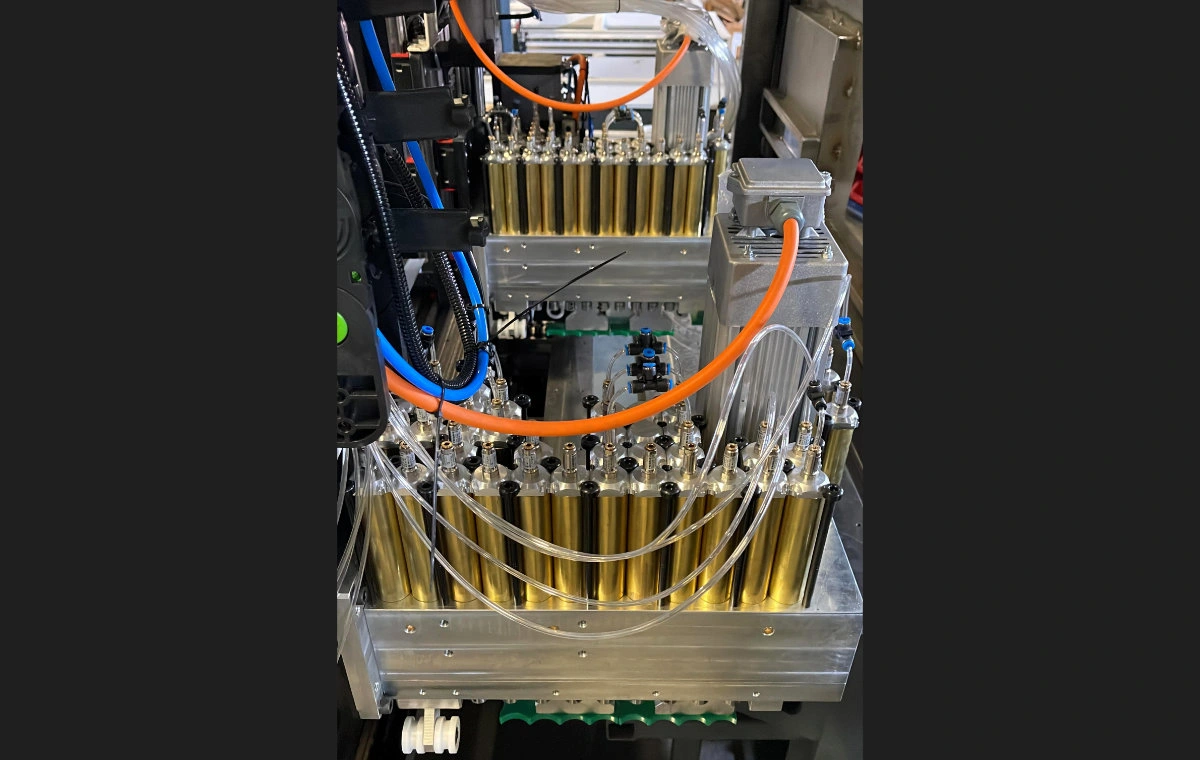

UPPER + LOWER DRILLING HEAD CONFIGURATION

- 24 vertical spindles

- 4 + 4 horizontal spindles along X-axis

- 4 + 4 horizontal spindles along Y-axis

- Blade Unit 120 mm Ø

- Drilling Unit power 2.2 kW (3 Hp)

- 10 lower vertical spindles

ELECTROSPINDLE 8 kW (9.5 Hp) + LOWER 1,8 kW (2 Hp)

Two air flotation tables, at the input and output, guarantee high smoothness of the panel. The fan is located under the rear level, easy to access and clean.

All products comply with the current CE regulations in force for dust extraction, noise and safety.

STRENGTHS POINTS

Axis movements on pinion and rack with ETHERCAT digital drives, even on the Z-axis to keep high working speeds and maximum precision.

Squaring on the 4 sides of the panel.

Possibility of working doors with angular transmission and anti-rotation flanges (opt).

All upper electrospindles are cooled by compressed air for prolonged use, lasting over time and without loss of performance.

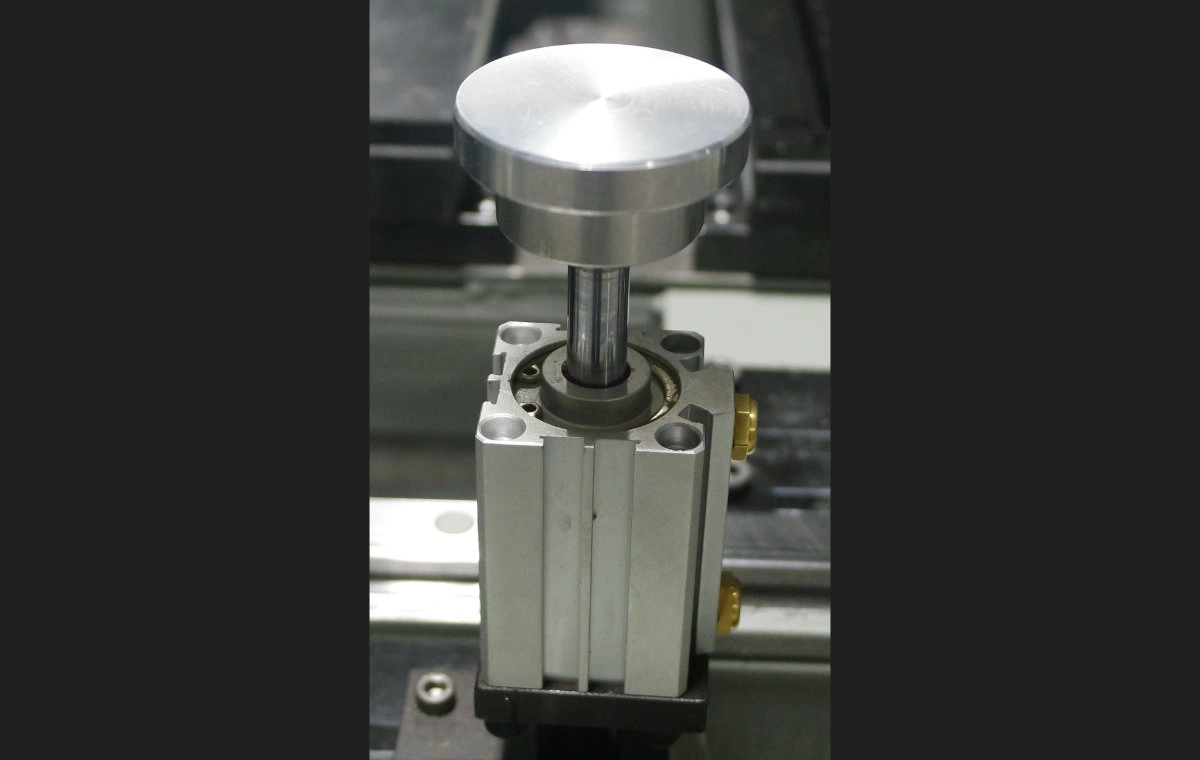

Pneumatic block for working hard materials.

Video

Dedicated accessories

- SAVE ENERGY pneumatic electrical cabinet Air conditioning.

- Automated loading and unloading.

- Possibility of customer-specific machine and software development.

Dedicated software

- TPA CAD graphic programming system – created in a Windows® environment,

offers a simple and functional interface. - Parametric programming.

- MACMAZZA programming CAM for machine logic management.

- Cycle optimization.

- Creation of TECNOTOOLS tool databases, with the aid of graphics and photos.

- Drawing reading in import and export in DXF and ISO format.

- Customizable job database.

- Creation of programs using specific macros.

- 3D visualization of the panel and individual work faces.

- Highly customizable macro programs for emptying, radiusing and squar

Technical sheet

| Panel width max-min (Y) | 1200mm – 50mm |

|---|---|

| Panel lenght max-min (Y) | ∞ – 150 mm |

| Panel thickness max-min | 60mm – 8mm |

| Axis stroke | 4000mm(X)-1200mm(Y) |

| Axis rapid speed | 120 m/min |

| Vertical spindles | 24+10 |

| Horizontal spindles | 4+4(X)-4+4(Y) |

| SAW BLADE | 2 X 120mm |

| Dust extraction hood | 2 X Ø 140 mm |

| Air pressure required | 8 bar |

| AUTOMATIC LUBRICATION | STANDARD |

| MACHINE STATUS LED | STANDARD |

| Automatic blowing rack cleaning | STANDARD |

| CE REGULATION | STANDARD |

Quality

High quality mechanical components, long life and reliability.

Efficiency

Compact and high-performance. Quick setup and simplified production processes. Greater automation and flexibility in the costing of the final product.

Easy to use

Intuitive, fast and efficient software. Work lists for easy production start-up.

Environment

Suction system for a clean and comfortable environment.