Processing cycles

Reinforced platform directly loadable with a forklift truck (up to 6.5 tons.)

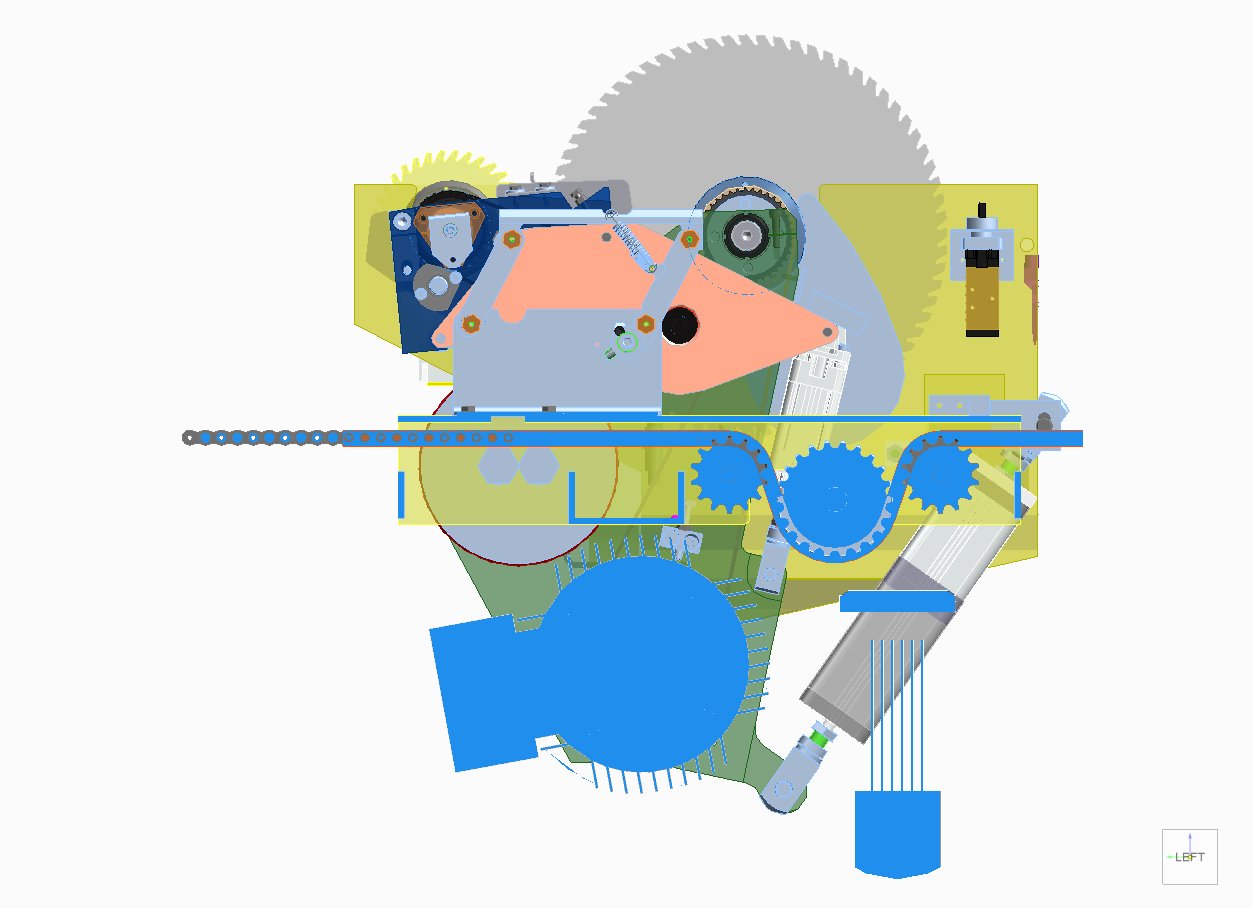

and electronically controlled axis (Encoder-Rack).

Roller Lateral Load (Optional).

Automatic loading of the thin patented

Pusher / pliers / Control proximities (instead of mechanical limit switches).

Reinforced tubular beams and precision rack. Linear variation in the speed automatic.

Zinc coated tables with special plastic wheels and cross stops

Patented grooved Pressore with additional pistons for uniform pressure along the entire length.

Automatic aligner for transverse cuts.

Plans air blowing for easy handling of strips until the transverse cutting and packages for pre-cuts.

Carro blade. Engraver postforming. external and electronic adjustments.

Chucks tires. Linear guidance. blade projection 150 mm.

Bispalla base with double guide for the weight balance in the center Warranty

and special anti-vibration running shoes.

Suction outlets.

Electronic control system with double microprocessor multitasking.

Graphic software in windows with simulations, diagnostics (Photographs of alarms, spare parts and maintenance Video) statistics (with cost and efficiency parameters) and optimizations.

Switchboards and pneumatic components with the best brands.

Complete cycle of flexible angular plant processing ‘TOP SAW W N E’ full optional.

Detail of the electronic transverse positioner on linear guides.

Automatic Processing lines for bars post-forming strips or pre-edged.

Electronic adjustment blades.

TRIANGULAR plant cutting with automatic loading, double automatic unloading and final packaging in line.