Description

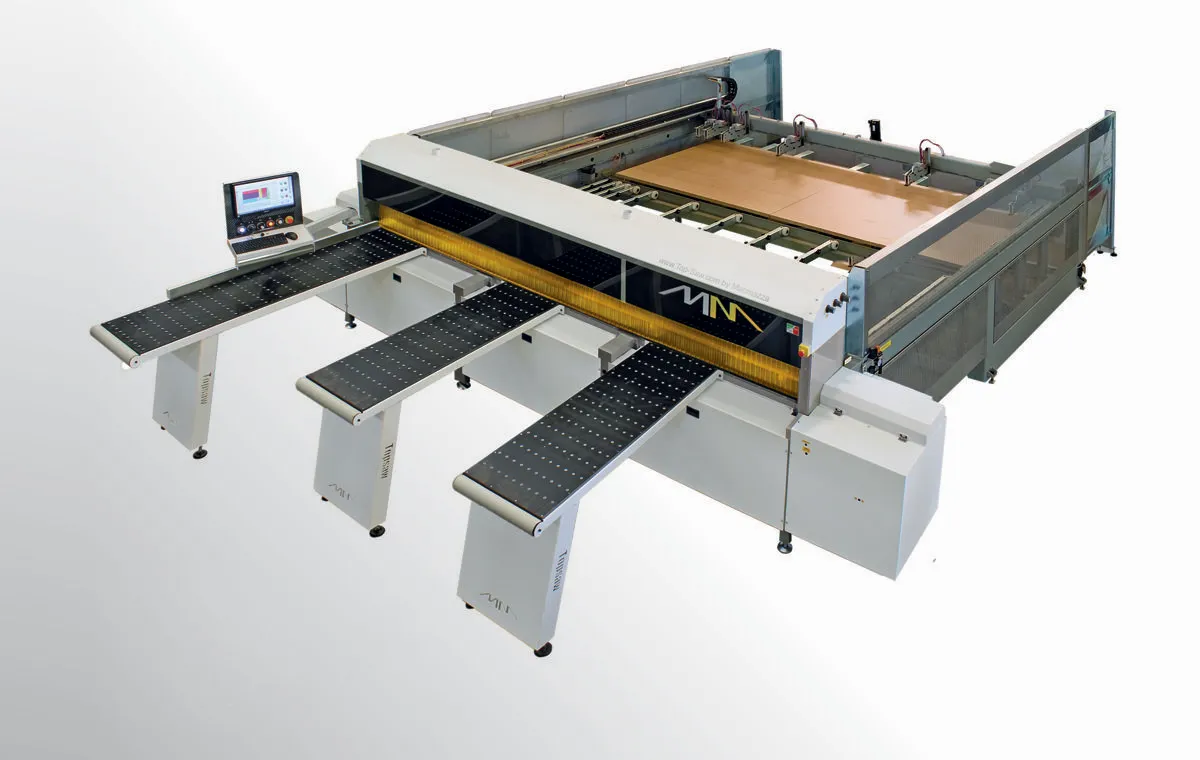

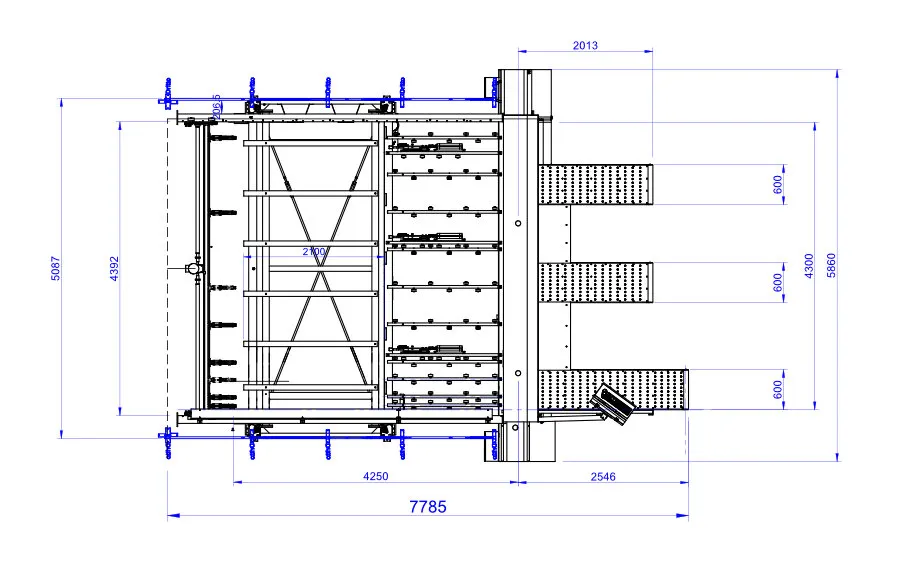

The TS-90P panel saw, with a cutting line of 4300 mm, takes up a space of 5860 mm, which is the same space required by competitors that cut 3200 mm.

The automatic rear loading allows to obtain a defined and efficient workflow, with the possibility of loading a standard 600 mm high package and a maximum capacity of 65 q.

The platform structure is monolithic and reinforced by crosspieces to avoid damage over time due to the loading of the panel packages.

The wider front machine is very useful for easily moving even the smallest panels. This allows the operator to complete transversal cuts while other panels are loaded without stopping the cycle. The panel parts to be recycled to optimize cutting can be easily parked and rotated (up to 5 cutting levels) by a single operator on wider and longer tables, without having to unload and reload them. It is also possible to pre-cut 2 packs at the same time, improving productivity, reducing manual work and waste.

The horizontal panel saw is an investment that lasts at least 20 years. The 4300 mm cut has a very high market value, also for easy resale of the used one. In addition, experienced customers prefer machines that can make longer cuts, as over time the panels become larger, allowing for greater production with less waste, less labor and lower costs. Across Europe, there has been a shift from smaller panels to panels up to 6000 mm. Those who have purchased a machine with a larger cut will not have to replace it.

All products comply with the current CE regulations in force for dust extraction, noise and safety.

Dimensions

STRENGTHS POINTS

4300 mm cutting line with the footprint of a classic 3200.

platform lifting by means of 4 recirculating ball screws

GRIPPERS with double stop and central nail that tightens in an arch (not a hammer) to avoid moving the pack of panels already at the stop fence (They have the negative effect of moving slippery panels away from the stops)

Cutting height 72 mm (4 panels 18 mm thick)

THK linear guides for a guarantee of smoothness and precision that lasts over time.

Power available up to 20 hp – 14 kW

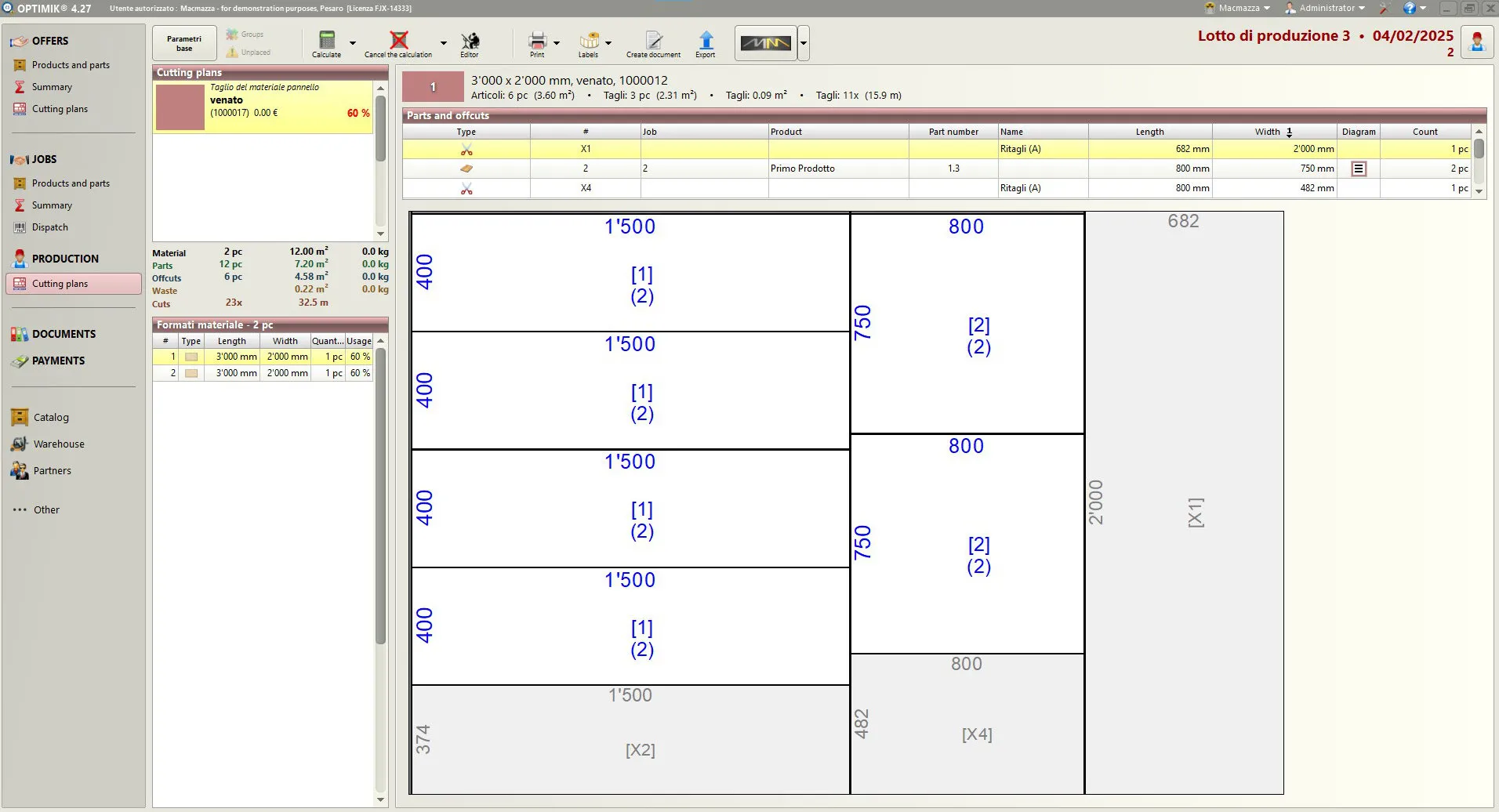

Software with unlimited optimizer and material warehouse.

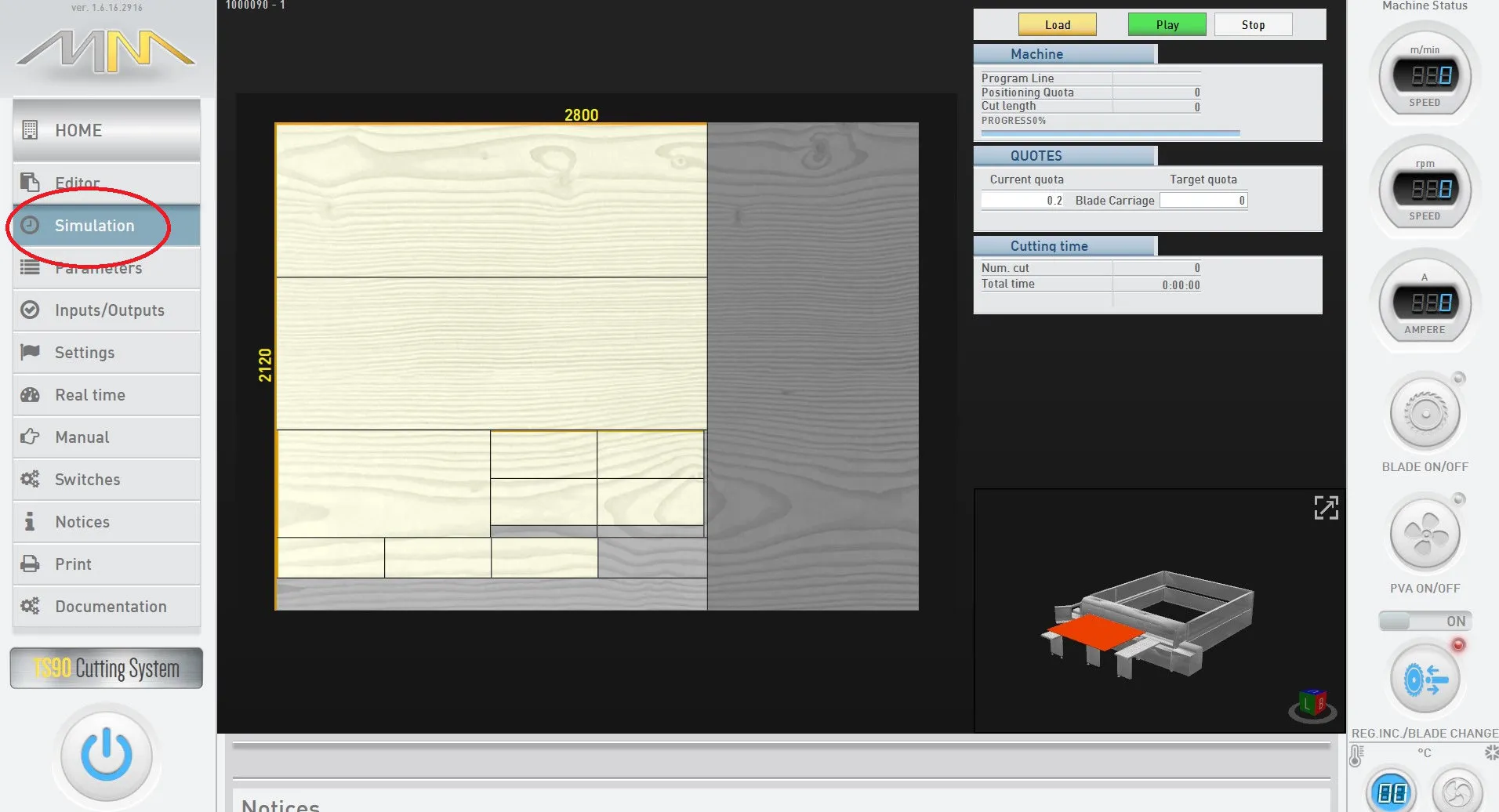

Video

Rear and cutting load

Optional Automatic Packaging

Cutting the panels 4 to 25 meters per minute!

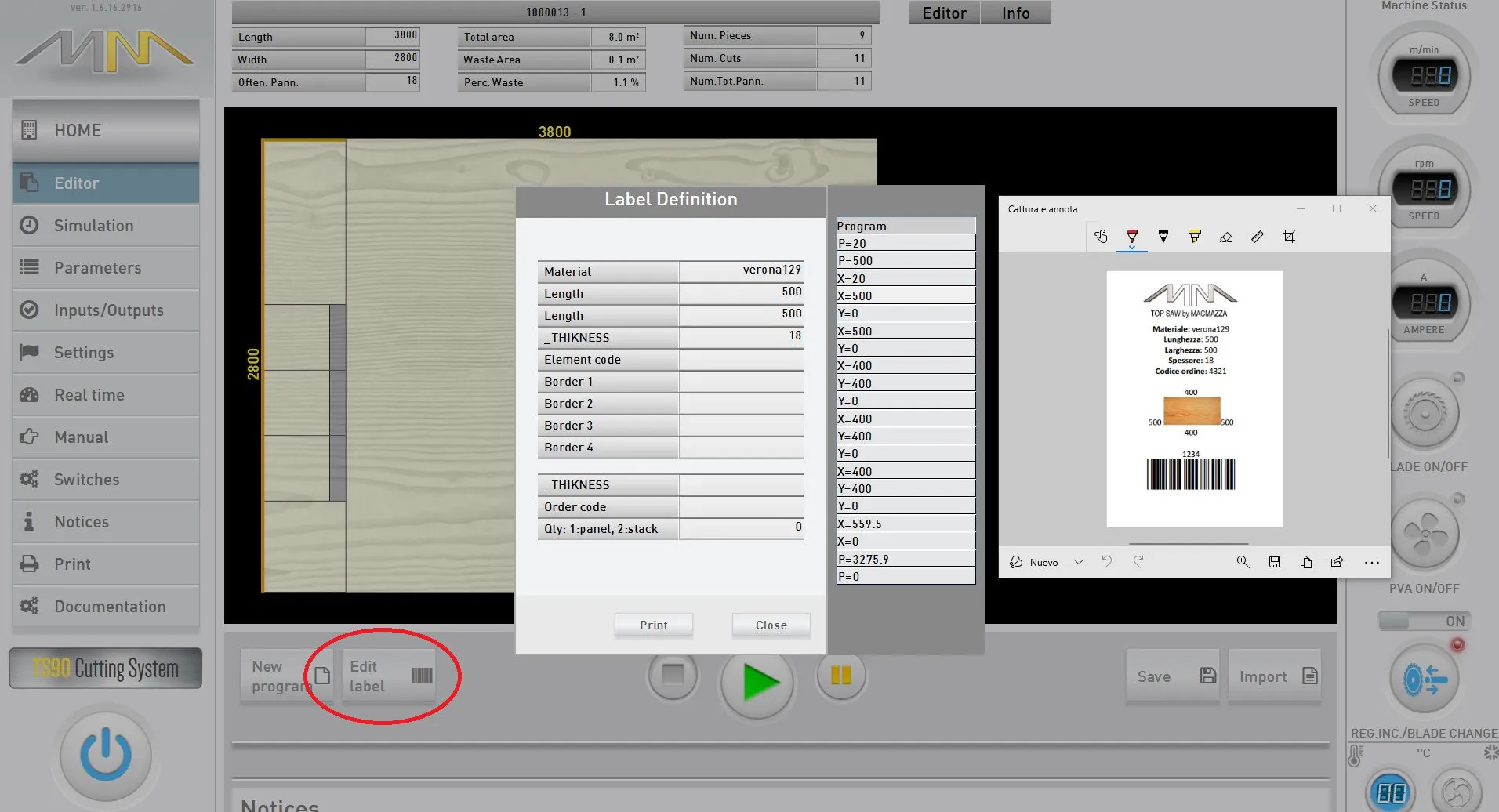

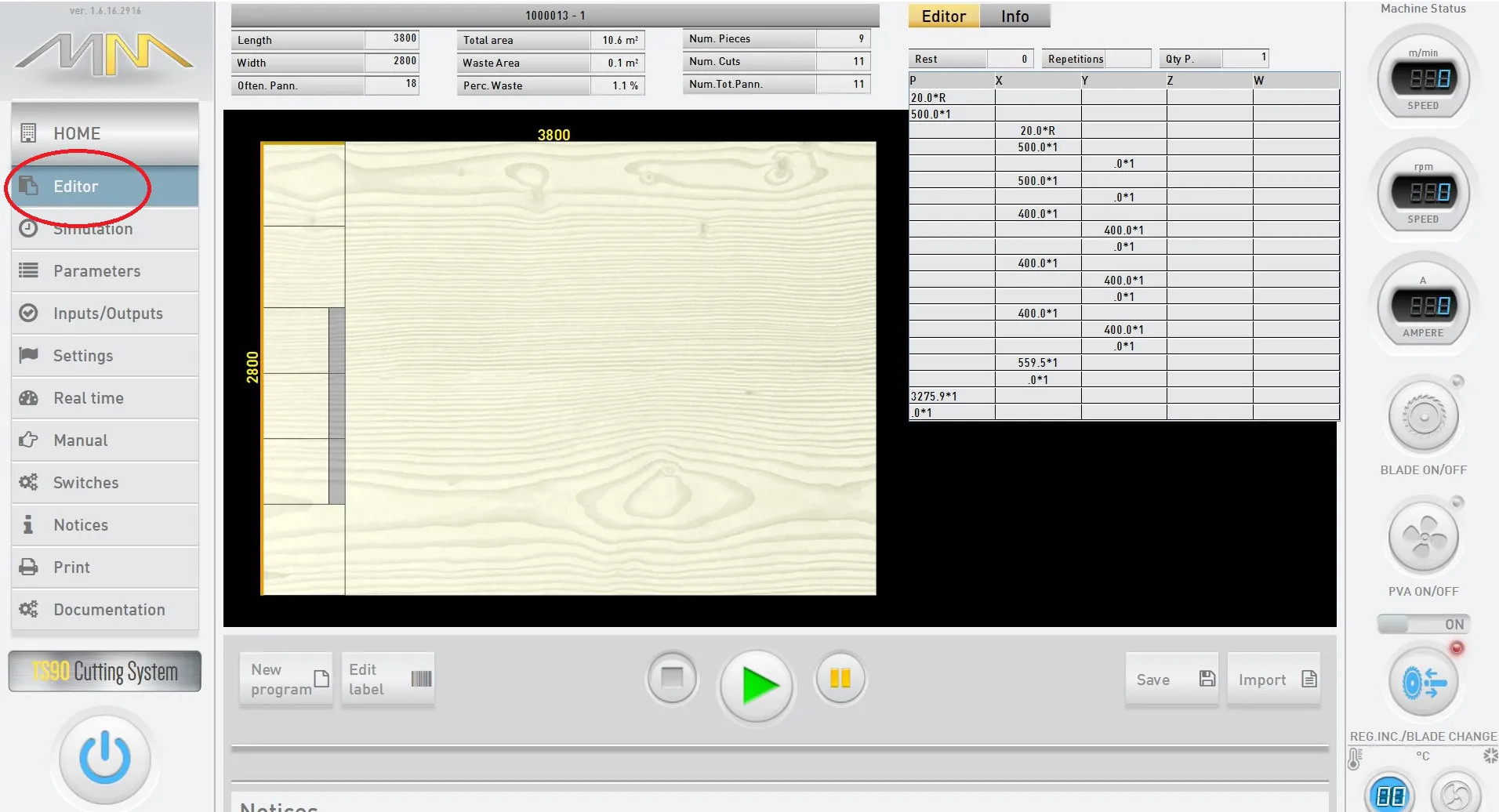

Dedicated software

PC + label printer + cutting program with cutting pattern display on the machine.

Unlimited optimization program in the office or on the machine.

Complete CAD design of the parts, without any size limit.

Possibility of also programming pre-cuts to obtain minimum waste.

Additional office program license including optimization interface.

Storage of panels and parts to be recycled, indication of edges from the edgebanding warehouse.

Products, optionals, accessories

INDUSTRY 5.0 Application of double inverter for blade shaft rpm variation, with the following advantages:

- optimize the cutting speed depending on the required quality and the type of material.

- optimization of the motor power to avoid overheating, reduce weight and carry out significant energy savings (at least 30% of current)

- greater feed speed and lower consumption of blades.

- Air blow for blade cooling, gluing powders and greater cleanliness.

Technical sheet

| Cutting length | 4300 mm |

|---|---|

| Effective Cutting Height | 72 mm |

| Motor power | 10 – 20 hp |

| Main blade diameter | 220 min – 325 max (mm) |

| Weight | 7000 kg |

| Dust extraction hood diameter | 2×120 mm 2×100 mm |

| Velocità avanz carro lame | 3-50 m/min |

| Saw carriage return speed | 30-120 m/min |

| Pusher speed | 2-25 m/min |

| Pusher return speed | 25-70 m/min |

| Suctions | 4000 m³/h 2500 N/m² |

Quality

High quality mechanical components, long life and reliability.

Efficiency

Compact and high-performance. Quick setup and simplified production processes. Greater automation and flexibility in the costing of the final product.

Easy to use

Intuitive, fast and efficient software. Work lists for easy production start-up.

Environment

Suction system for a clean and comfortable environment.